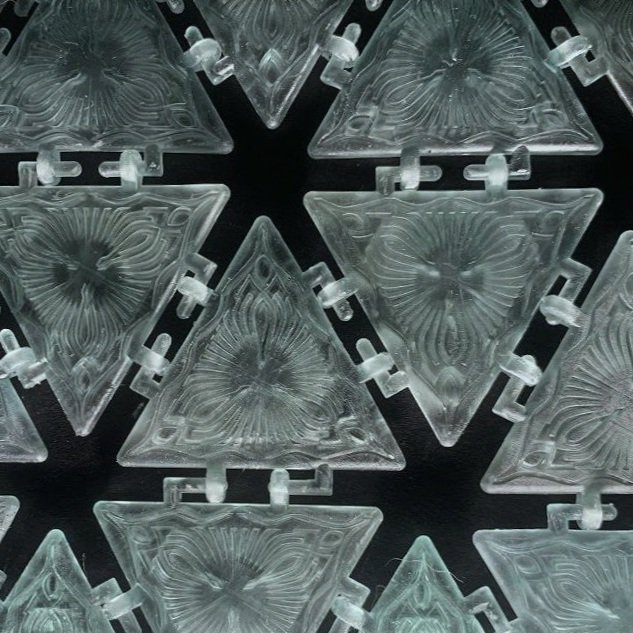

Modular building units

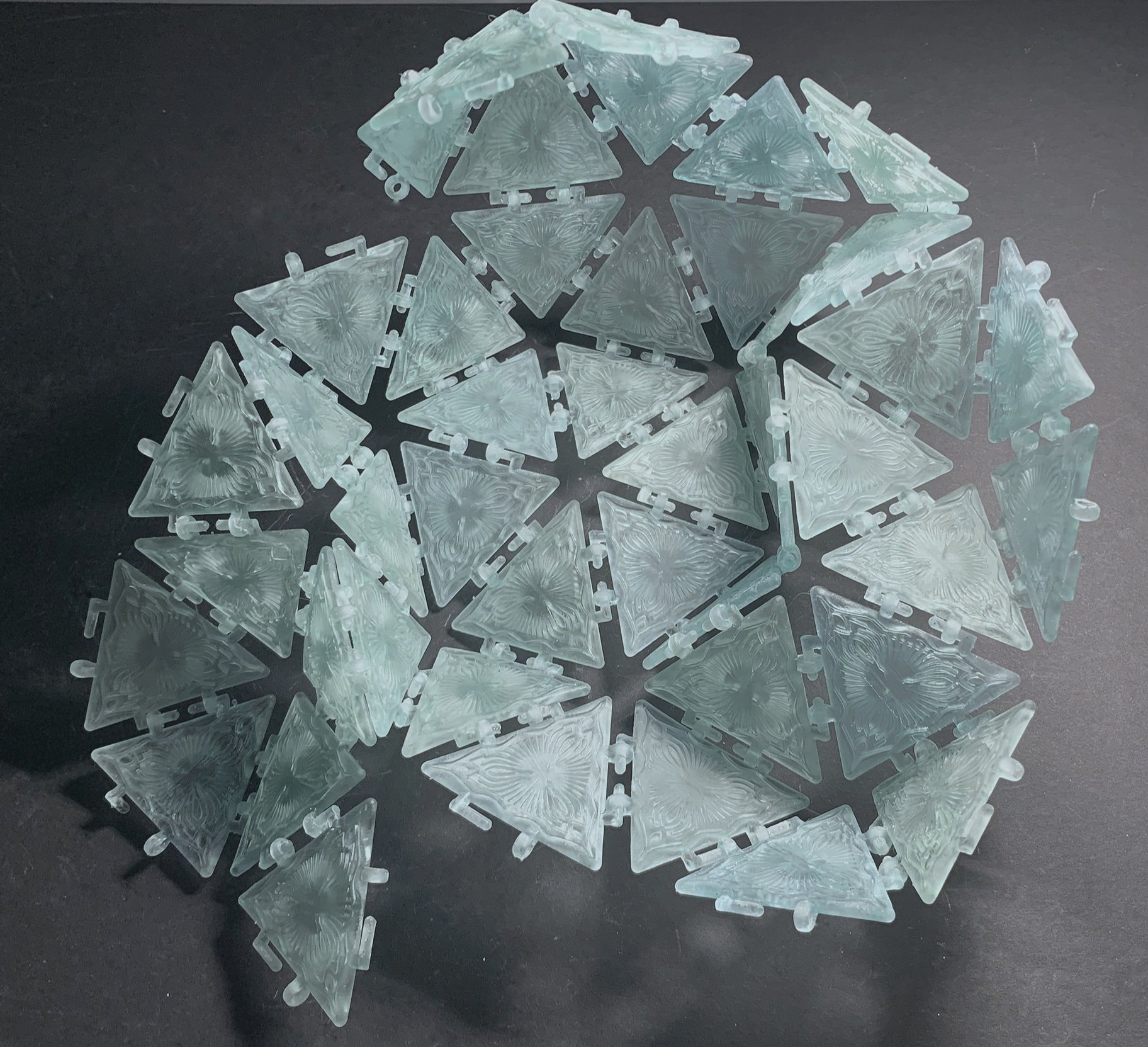

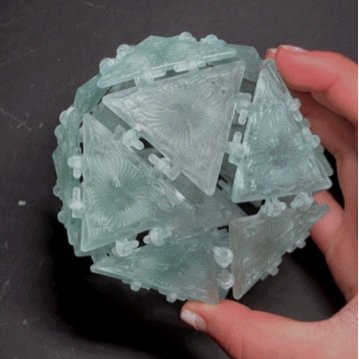

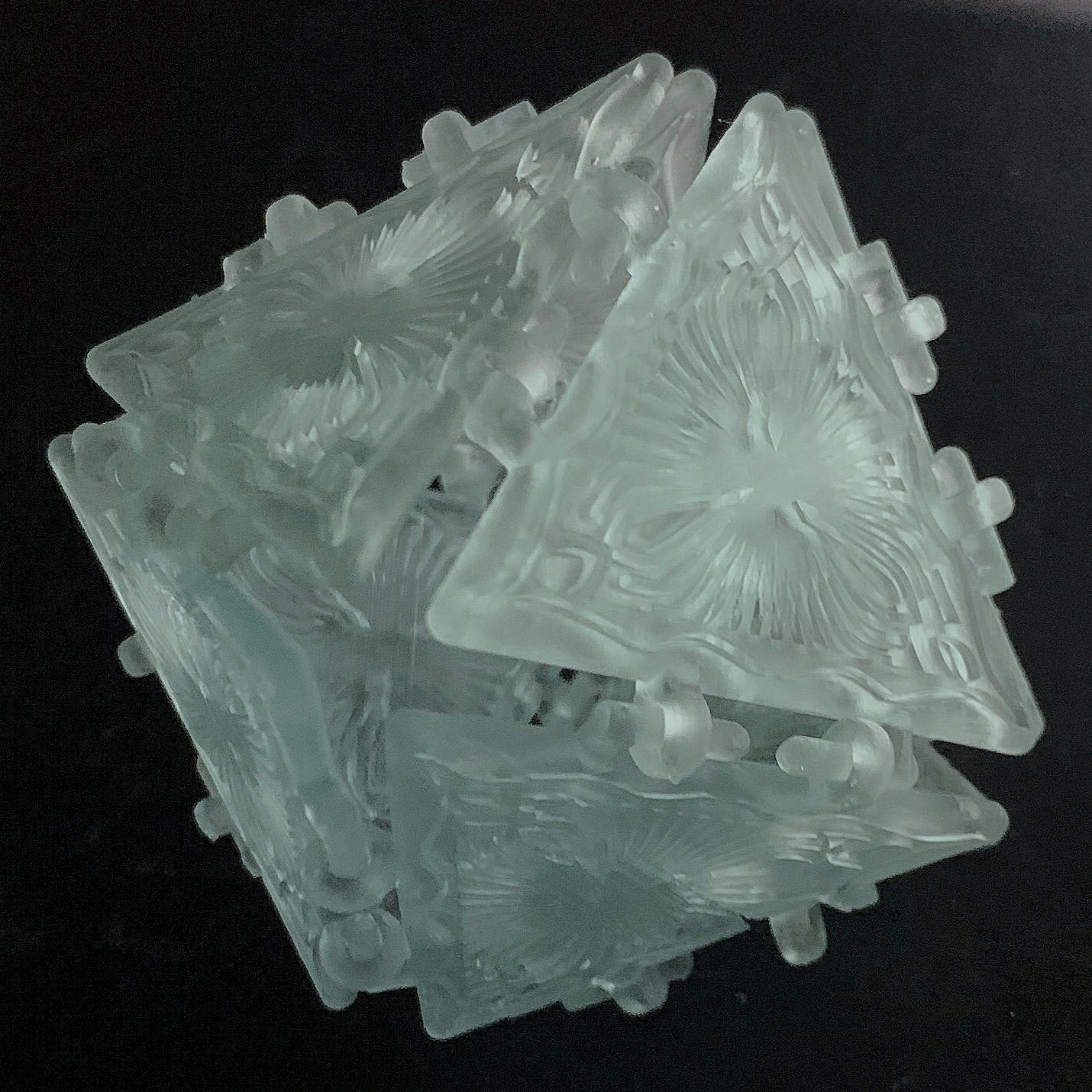

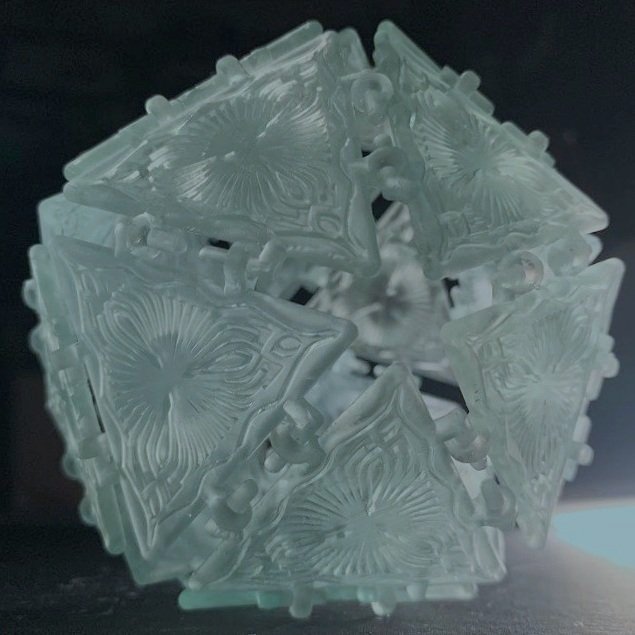

From growing up on LEGO technic sets and K’NEX, and working with elementary school students over lockdown, I was inspired to create a construction toy of my own. The unit itself is a simple equilateral triangle, modeled based on triangular centric diatoms. I researched multiple forms of joining the units, and settled on my design as it was the most user-friendly, and lent itself well to printing. I plan to explore articulated print-in-place joints in the future, but the key here is being able to assemble and disassemble each part. The units are designed on Fusion 360, then resin printed. Below are the two versions I ran through, until I decided on an attachment method and design.

Some examples of structures I created. From 3D geometry to freeform sculpting.

Eye Drop Cutter

This project attempts to create an attachment that reduces the volume of eye drops. Still in progress - updates to come!

MASKs

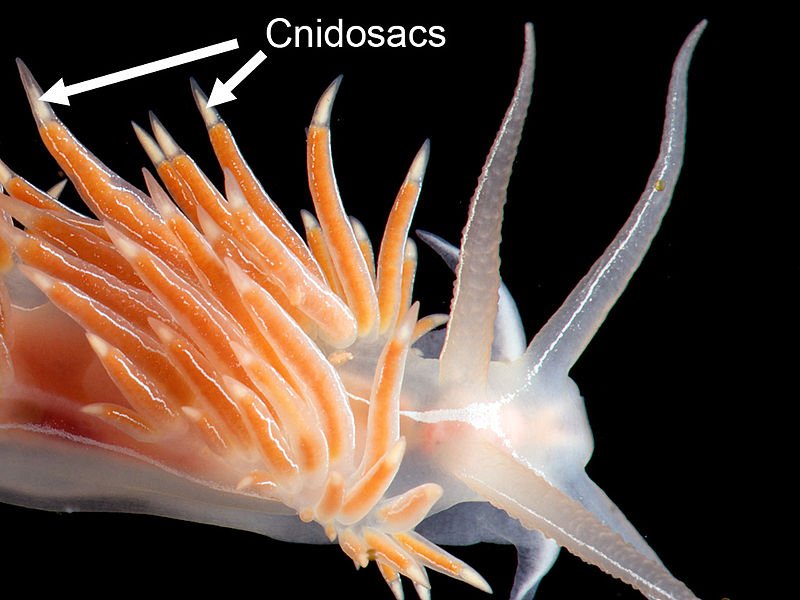

Inspired by the tentacles of the yellow wandering anemone, the appendages of the antillean file clam, and the cnidosacs on the tips of a nudibranch’s cerata.

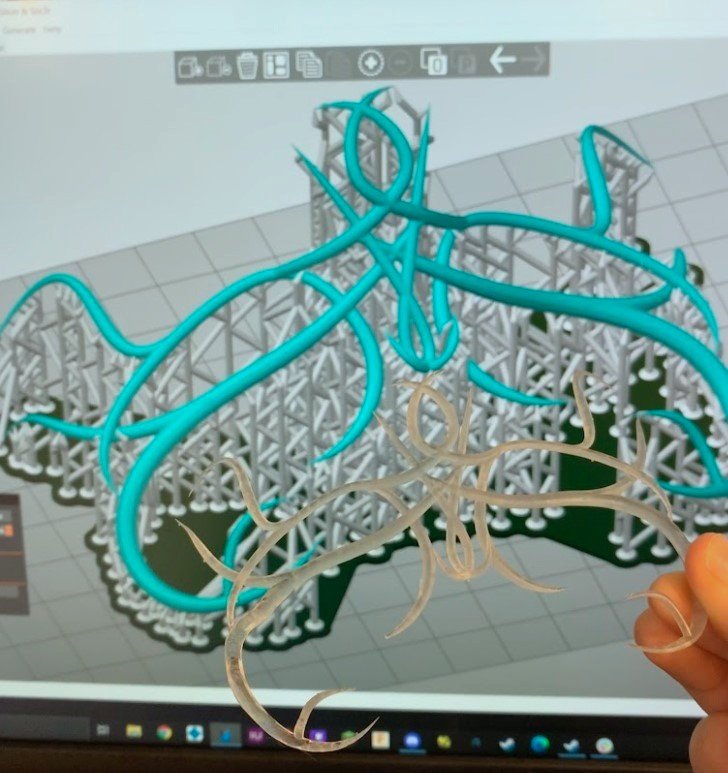

Process

The models were created in Blender, as the software lends itself to organic shapes, and allows easier sculpting. The final models were then scaled based on my interpupillary distance so that they would fit my face. In order to capture the essence of my inspiration, the ends of my prints came to many sharp points, and the structure of the prints was very thin. It took many tries to print the finished pieces, a combination of trial and error as I figured out the supports, mixed the correct ratios of resin for maximum strength and flexibility and shortened/thickened portions of my design.